Product Description

Product Information

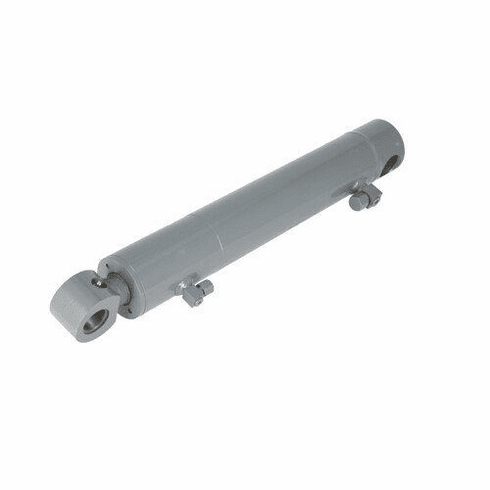

High quality CHINAMFG CaterpiIIar Blade Tilt Cylinder LH D10T 2320652/G hydraulic cylinder

| Working temperature | -40°C ~ 80°C |

| Color | RAL9005,Customize |

| Material | CK45,ST52,ST52-3,27SiMn,Customize |

| Seal kit | SKF, Trelleborg, Halite, Chesterton, NOK, Kayaba |

| Piston rod | Hard chromed |

| Packaging | Plywood case |

| Warranty | 12 months |

| Payment | T/T |

| Part NO. | Name of Commodity & Specification | Model | Measurement(CMS) | Volume | Net Weight(kg) | Gross WT (kg) | ||||

| Length | Width | Height | m³ | Unit | Total | Unit | Total | |||

| 2320652/G | D10T Cat truck | D10T | 205.00 | 50.00 | 60.00 | 0.62 | 350.00 | 350.00 | 410.00 | 410.00 |

Popular Cylinder Type and Part No. for Mining Haul Truck

| Item No. |

Part NO. |

Name of Commodity & Specification |

Model |

| 1 | EJ6895/G | Front Suspension ASSY/830E Dump Truck | 830E |

| 2 | EM8840/G | Rear Suspension ASSY/830E Dump Truck | |

| 3 | EM8354/G | Hoist Cylinder ASSY/830E Dump Truck | |

| 4 | EL7952/G | Steering Cylinder ASSY/830E Dump Truck | |

| 5 | 9T2869/G | Blade Hoist Cylinder | D10T |

| 6 | 2320652/G | Blade Tilt Cylinder LH | |

| 7 | 2320653/G | Blade Tilt Cylinder RH | |

| 8 | 19926445/G | Ripper Lift Cylinder RH | |

| 9 | 19926446/G | Ripper Lift Cylinder LH | |

| 10 | 4T9977/G | Ripper Tilt Cylinder | |

| 11 | 252571/G | Blade Hoist Cylinder | D11T |

| 12 | 3672259 /G | Blade Tilt Cylinder LH | |

| 13 | 3672258 /G | Blade Tilt Cylinder RH | |

| 14 | 1616616/G | Ripper Lift Cylinder LH | |

| 15 | 1616615/G | Ripper Lift Cylinder RH | |

| 16 | 1306381/G | Ripper Lift Cylinder LH | |

| 17 | 1303263/G | Ripper Lift Cylinder RH |

Advantage

Better designs, better material, better value.

ROCA hydraulic cylinders are designed with rugged features to give unequaled service life and performance.

Mining equipment is continually subjected to torturous conditions that punish hydraulic cylinders. These difficult conditions include dust, grit, heat, cold, and moisture. Besides, the equipment is subject to slamming loads and mechanical impacts.

ROCA designs and manufactures excavators, dumper trucks, and heavy-duty hydraulic cylinders that endure these very difficult conditions.

Show

Shipment

Company Information

HangZhou CHINAMFG is a comprehensive manufacturing enterprise engaged in hydraulic cylinders, excavator attachment, metal casting, hydraulic components with certification approval to meet custom or OEM requirements.

ROCA owned factory offers customer effective-cost product with quality assurance. With its professional and experienced R&D team, CHINAMFG Hydraulic devotes itself to research and development to optimize products applied in construction, mining, waster management, forestry, agriculture, etc.

Hydraulic cylinders are the most effective and efficient method of pushing, pulling, lifting, and lowering.

Nowadays hydraulic cylinders play an essential role in daily application and industry:

√ Mining

√ Earthmoving & Construction

√ Agriculture &Forestry

√Waste Management & Material Handing

√Ship crane & offshore

Selecting the right cylinders for an application is critical in obtaining maximum performance and reliability.

ROCA team takes all your concerns into consideration to suit your hydraulic cylinder requirements.

Together, we work out the best design solution for your application.

FAQ

1. What is the Warranty Period?

Generally 12 months from the date of bill of lading. For some special machines, the warranty can be prolonged after mutual agreement.

2. Which Payment Terms Can you Accept?

1,L/C+T/T

2,L/C+D/P

3. How Is Your Delivery Time?

It depends on the type of machine. In general circumstances, it will take more than from 30days to 90days to finish production. But we always will try our best to advance the delivery. If the material is in handy, the production time will also be shortened accordingly.

4. How Soon Can You Respond to Client’s Inquiry?

As soon as we saw it, no more than 12hours.

| Certification: | CE, ISO9001 |

|---|---|

| Pressure: | High Pressure |

| Work Temperature: | Low Temperature |

| Acting Way: | Double Acting |

| Working Method: | Straight Trip |

| Adjusted Form: | Regulated Type |

| Customization: |

Available

|

|

|---|

How does a tilt cylinder contribute to precise equipment positioning?

A tilt cylinder plays a crucial role in achieving precise equipment positioning. It provides the necessary force and control to adjust the tilt angle of the equipment, allowing operators to position it accurately for various tasks. Here’s a detailed explanation:

- Tilt Angle Adjustment: A tilt cylinder allows operators to adjust the tilt angle of the equipment. By actuating the cylinder, they can tilt the equipment forwards or backwards, facilitating precise positioning. The ability to fine-tune the tilt angle enables operators to align the equipment with specific targets or work areas, ensuring optimal accuracy and efficiency.

- Load Distribution: Precise equipment positioning is essential for maintaining proper load distribution. A tilt cylinder allows operators to adjust the tilt angle to distribute the load evenly across the equipment. This is especially important when handling uneven or imbalanced loads. By achieving precise positioning through tilt cylinder control, operators can optimize load distribution, minimize stress on the equipment, and enhance stability during operation.

- Contour Adaptation: In certain applications, such as land grading or earthmoving, precise equipment positioning is necessary to adapt to the contours of the terrain. A tilt cylinder enables operators to adjust the equipment’s tilt angle to match the slope or shape of the ground. This contour adaptation capability ensures consistent contact with the surface, promoting uniform grading or excavation and achieving the desired results with precision.

- Height Adjustment: Some tilt cylinders also allow for height adjustment in addition to tilt angle adjustment. By extending or retracting the cylinder, operators can raise or lower the equipment’s position. This height adjustment capability further enhances precise positioning, enabling operators to align the equipment at the desired elevation for specific tasks or working conditions.

- Integration with Control Systems: Tilt cylinders can be integrated with advanced control systems in modern equipment. These control systems may include electronic or hydraulic controls that allow for precise and automated tilt angle adjustments. By utilizing such systems, operators can achieve highly accurate and consistent equipment positioning, reducing human error and improving overall productivity.

- Operator Feedback: Tilt cylinders equipped with sensors or feedback mechanisms can provide real-time information to operators about the equipment’s tilt angle. This feedback allows operators to make precise adjustments and ensure accurate positioning. By continuously monitoring the tilt angle, operators can maintain the desired position during operation and make necessary corrections as needed.

Therefore, a tilt cylinder contributes significantly to precise equipment positioning by enabling tilt angle adjustment, load distribution optimization, contour adaptation, height adjustment, integration with control systems, and operator feedback. These capabilities enhance the accuracy, efficiency, and versatility of equipment in various industries, including construction, material handling, agriculture, and more.

Can tilt cylinders be used in material handling equipment for load manipulation?

Yes, tilt cylinders are commonly used in material handling equipment for load manipulation. These cylinders play a crucial role in enhancing the versatility and efficiency of equipment designed for lifting, moving, and manipulating various types of loads. Here’s a detailed explanation:

- Load Tilting: Tilt cylinders enable material handling equipment to tilt loads, allowing for precise positioning and manipulation. By adjusting the tilt angle, operators can optimize load distribution, accommodate uneven surfaces, and ensure secure handling. Tilt cylinders provide the necessary force and control to achieve the desired load tilting, enhancing safety and operational efficiency.

- Load Stabilization: In material handling applications, load stability is essential to prevent shifting, sliding, or toppling during transport or manipulation. Tilt cylinders contribute to load stabilization by allowing operators to adjust the load tilt angle and maintain a stable position. This feature is particularly important when dealing with unbalanced or irregularly shaped loads. By utilizing tilt cylinders, material handling equipment can ensure safe and secure load manipulation.

- Load Dumping: Tilt cylinders also facilitate load dumping in certain material handling equipment. For example, in dump trucks or dumpers, tilt cylinders allow the controlled tilting of the cargo bed to unload the materials. By actuating the cylinders, operators can achieve controlled and efficient dumping of the load, minimizing material waste and optimizing productivity.

- Load Rotation: Some material handling equipment, such as rotating telehandlers or rotating fork attachments, utilize tilt cylinders to enable load rotation. By adjusting the tilt angle, the equipment can rotate the load horizontally, providing flexibility in positioning or transferring materials. Tilt cylinders provide the necessary force and control for smooth load rotation, expanding the equipment’s capabilities.

- Integration with Hydraulic Systems: Tilt cylinders are integrated with hydraulic systems present in material handling equipment. Hydraulic power is utilized to actuate the cylinders, providing the required force and control for load manipulation. The hydraulic system allows for precise and responsive movement, enabling operators to adjust the load tilt angle according to specific requirements.

- Customization and Compatibility: Tilt cylinders can be customized to suit different types of material handling equipment and load manipulation applications. Manufacturers offer tilt cylinders with varying specifications, such as different force capacities, stroke lengths, and mounting options, to ensure compatibility and optimal performance. This customization allows for seamless integration and enhances the overall functionality of material handling machinery.

Therefore, tilt cylinders are widely used in material handling equipment for load manipulation tasks. Whether it involves load tilting, stabilization, dumping, or rotation, tilt cylinders provide the necessary force, control, and flexibility to handle various loads efficiently and safely. Their integration with hydraulic systems and customization options make them indispensable components in material handling applications.

How does a tilt cylinder handle variations in equipment tilt and positioning?

A tilt cylinder is designed to handle variations in equipment tilt and positioning by incorporating specific features and mechanisms. These features allow the tilt cylinder to adapt to different angles and positions effectively. Here’s an explanation of how a tilt cylinder handles variations in equipment tilt and positioning:

- Range of Motion: Tilt cylinders are engineered to provide a wide range of motion. They can tilt or angle components within a specified range, allowing for various positions and angles. The range of motion is determined by the design and construction of the cylinder, as well as the attachment points on the equipment. This versatility enables the tilt cylinder to accommodate different tilting requirements and adapt to varying equipment positions.

- Control Valves: Tilt cylinders are equipped with control valves that enable precise control over the tilting movement. These valves regulate the flow and direction of hydraulic fluid, allowing operators to control the speed, extent, and direction of the tilt. By adjusting the control valves, operators can fine-tune the positioning of the equipment, compensating for variations in tilt and ensuring accurate alignment.

- Feedback Mechanisms: Some tilt cylinders incorporate feedback mechanisms such as limit switches or sensors. These mechanisms provide real-time feedback on the position and angle of the tilted component. By monitoring the feedback, operators can precisely adjust the tilt cylinder to compensate for variations in equipment tilt and positioning. This ensures that the component remains in the desired position and angle, enhancing operational efficiency and safety.

- Hydraulic System Control: The hydraulic system that powers the tilt cylinder plays a crucial role in handling variations in equipment tilt and positioning. The hydraulic system includes pressure regulators, flow control valves, and other components that allow operators to finely adjust the hydraulic pressure and flow. By manipulating the hydraulic system controls, operators can compensate for variations in equipment tilt and achieve the desired positioning with precision.

- Robust Construction: Tilt cylinders are built with robust materials and construction to withstand variations in equipment tilt and positioning. They are designed to handle high loads and resist external forces that may impact the tilting movement. The robust construction ensures the durability and stability of the tilt cylinder, enabling it to maintain consistent performance even in challenging operating conditions.

Overall, a combination of factors such as the range of motion, control valves, feedback mechanisms, hydraulic system control, and robust construction allows a tilt cylinder to handle variations in equipment tilt and positioning. These features work together to ensure precise control, adaptability, and stability, enabling the tilt cylinder to effectively handle different angles and positions of the equipment it is attached to.

editor by CX 2023-11-02